The Age of the Industrial Metaverse in the Energy Sector

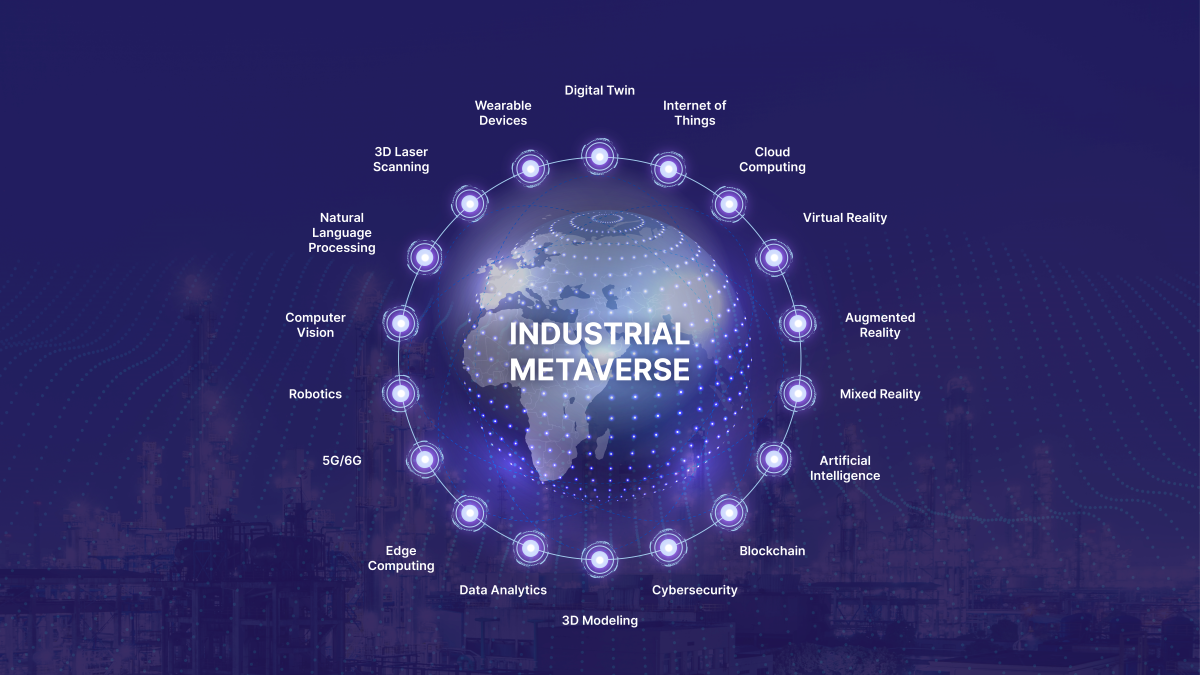

The dawn of the industrial metaverse approaches offering a new, technology-infused horizon for industries worldwide. Commonly referred to as the Industrial Metaverse, this digital ecosystem ingeniously weaves together advanced technologies like digital twins, virtual reality (VR), augmented reality (AR), artificial intelligence (AI), and the Internet of Things (IoT).

The industrial metaverse embodies an immersive, real-time, collaborative environment that seamlessly blends the digital and physical realm. This integration leads to streamlined workflows, improved communication, optimised processes, enhanced collaboration, and better decision-making.

In the energy sector, this digital revolution provides an array of practical applications. Such applications include immersive project progress and design reviews, virtual collaboration, intensive training, remote monitoring and maintenance of critical infrastructure, AI/ML model development and retraining, robotics and autonomous aerial vehicles R&D, and energy and emissions analysis and optimisation.

Consider the impact of the industrial metaverse on engineering design intelligent reviews, for instance. It enables real-time collaboration among teams scattered across different geographical locations. This reduces the time spent on revisions and enhances the quality of design, revolutionising the whole process.

Similarly, project progress reviews happen on an entirely different scale in the industrial metaverse. Stakeholders can virtually visit project sites to assess progress and address issues in real-time, resulting in greater collaboration and accuracy.

When it comes to training, the immersive experience of the metaverse accelerates learning and mitigates risks associated with on-site training in the energy industry. It also offers unprecedented possibilities for remote monitoring and maintenance. By integrating IoT devices, sensors, and real-time data, the industrial metaverse eradicates the need for on-site visits, enhancing operational efficiency and minimising downtime.

The metaverse also serves as a platform for the development and retraining of AI/ML models. These models can be put through a myriad of virtual simulations and tested under real-world conditions, improving their accuracy and performance.

The research and development of robotics and autonomous aerial vehicles could be fundamentally transformed by the metaverse. Virtual simulations enable the design and prototyping of new robots, facilitating communication and collaboration on robot projects.

The industrial metaverse also has the scope to revolutionise energy and emissions analysis and optimisation. It has the power to identify inefficiencies and fine-tune facility emissions at every stage of the lifecycle.

With such potential, the Industrial Metaverse promises to revolutionise operations in the energy industry, enabling seamless interactions between people, assets, processes, and objects from anywhere in the world. It has the capability to effectively track energy consumption and pinpoint areas where energy is being wasted or can be optimized.

Moreover, the industrial metaverse facilitates the instant simulation of improvement actions, adding another layer of efficiency to processes. Embracing the Industrial Metaverse is not just an option but a crucial step for the future of the energy industry. Its multi-faceted advantages and pioneering application spell a paradigm shift for the energy sector, ensuring enhanced efficiency and sustainability.

By using our website you consent to all cookies in accordance with our Privacy Policy.